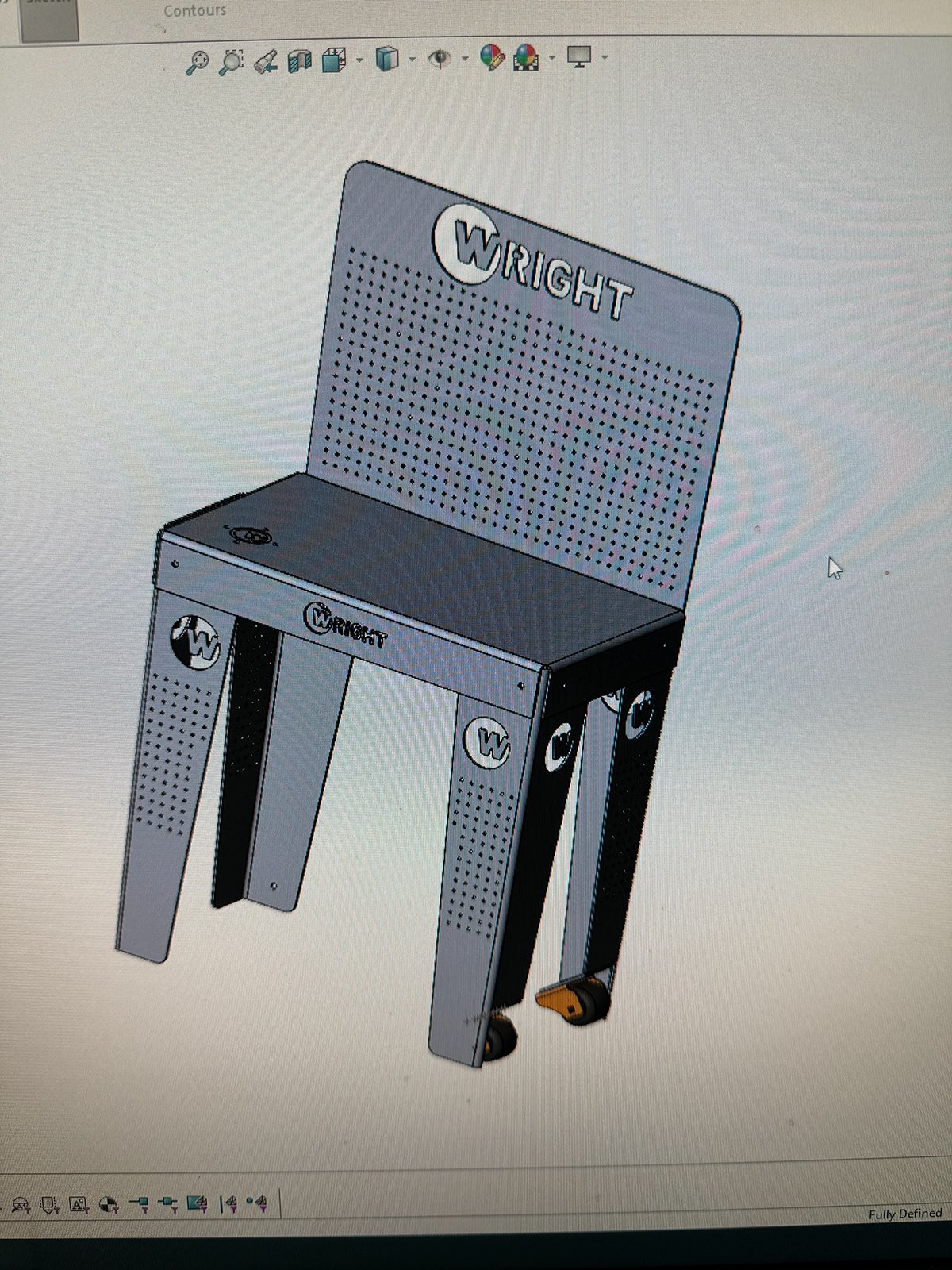

Work Bench

This workbench is being designed for a project during my internship at Wright Manufacturing. The goal is to create a table that can be used by mechanics working on our lawnmowers as well as by other companies, assisting them in making repairs more efficiently. Some of the key features include pegboards on the top backboard and on the legs, providing adjustable storage to hold tools or spare parts. The legs have wheels to facilitate easy movement of the table and holes to allow the table to be bolted down. The tabletop has a special feature that makes it suitable for welding. Additionally, there is a hole on the tabletop designed for the placement of spindles, with a tray underneath to catch any loose bolts or grease, aiding in clean-up.

This table will be manufactured from different types of sheet metal, which will be laser-cut to shape and to create the necessary holes. After the sheet metal is cut, all the pieces that need bending will be shaped using a metal press. Finally, all the different pieces will be bolted together. This demonstrates my technical skills with the software SolidWorks and shows designing for a particular type of manufacturing because this was designed for sheet metal. In SolidWorks, this was designed with the consideration that it will be manufactured using a laser cutter and a press brake, which is a machine that bends sheet metal. It’s a similar concept to origami but with sheet metal. Keeping this in mind changes the design process. As the designer, I actually tell the computer how each part is going to be bent. Each machine also has its own requirements as well.